What is staggered edge end mill?

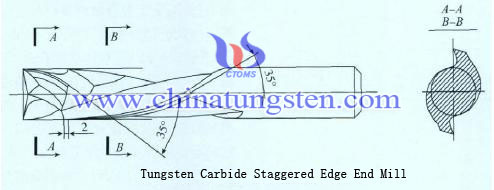

Staggered edge end mill is a kind of new special cutter for fiber composite materials, its cutting edge is divided into upper and lower parts, the workpiece material should be on the middle area under the producing process. Due to the use of a proximal portion of the cutting edge blade right-handed, left-handed blade near the handle of the staggered design, the lower end of the right-handed cutting edge end mill for milling under the surface, under the surface by the upward cutting force; standing upper cutter L on the cutting edge for milling the surface, on the surface by the downward cutting force. Thus, the material, the lower surface of the fibrous layer are completely cut off easily, effectively preventing the upper and lower surfaces of the workpiece tear, burrs and other processing defects.

Staggered Edge End Mill Advantages

Staggered edge end mills for processing, due to the workpiece, the lower surface being opposite to the direction perpendicular cutting force, the axial force is reduced and the total cutting force direction is always pointing to the inside of the material, not only the cutting process is relatively stable, but also effective inhibit the production of carbon fiber composite material processing defects and improve the surface quality of the work to extend the life of the end mill for milling of carbon fiber materials in line. Actual proof, under the same cutting conditions, staggered edge carbide end mill has good wear resistance, service life is 1.6 times that of ordinary carbide end mills. Abrasive wear and flaking of the coating is diamond-coated carbide end mills Milling fibers are mainly in the form of composite process tool wear.

Main Application of Staggered Edge End Mill

Spiral staggered around edge carbide end mill is mainly used for paper trimming and milling aramid honeycomb sandwich composites. Since the cutting edge of the tool is symmetrical about a staggered spiral, and helical cutting edge around the junction is always held in the neutral position of the paper and the aramid honeycomb sandwich structure, and therefore, in the trimming process, two surfaces of the sandwich structure cutting force is always toward the center of the sandwich structure, thus avoiding crack, layer or spinning phenomenon.

About processing interlaced composite spiral blade carbide end mills as shown in FIG. Carbon fiber composite material milling a carbon fiber composite material is formed mainly Milling excess portion after removal of the surrounding composite parts, while the carbon fiber composite material profile milling composite material mainly by part-surface forming process design requirements.

According to the processing characteristics of carbon fiber composite materials, carbon fiber composite milling and profile milling cutter mainly with independent intellectual property rights carbide "scale" Cutter, the advantages of the tool cutting edge is sharp, you can achieve high-speed cutting, reach in the milling and grinding effect, therefore, improve the processing efficiency and surface quality of the composite material, the better to prevent delamination of carbon fiber composite material or spinning and so on.

More Info>>

1.Tungsten Carbide

2.Tungsten carbide Bar

3.Tungsten carbide Rod

4.Tungsten Carbide Nozzle

5.Tungsten Carbide Button

6.Tungsten Carbide Inserts

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com ; sales@xiamentungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved