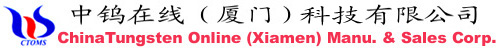

Tungsten carbide helix rod has high hardness (typically between HRA85 ~ 93), high strength (the compressive strength of 3400MPa ~ 560OMPa, flexural strength is 750MPa-2500MPa), high wear resistance (15 to 20 times higher than the best HSS), high heat resistance, strong antioxidant capacity and a series of advantages. It can be used to produce a variety of drills, high-speed milling tools .

|

|

|---|

Tungsten Carbide Helix Rod Production Process

Tungsten carbide helix rod manufacturing technology key is the helix hole formed, it mainly made by a metal powder injection molding technology. The process is: the mixture of metal powder and wax injection molding, and then paraffin is removed by sintering to obtain a high density tungsten carbide helix hole rods. Metal injection molding process as follows: mixing→glue→injection material→injection molding (mold)→green→lifted binder sintering→product. Metal powder injection molding production of tungsten carbide helix rod has high efficiency, high quality, precision, low power consumption advantages.

Tungsten Carbide Helix Rod Processing Methods

1. Billet processing method. The carbide bar prior to sintering the green compacts in drilling, the other end of the drilled hole at the same angle of 2-4.

2. Mosaic Law. This method is called sandwich method, sintering combination method. That is processed into a spiral flute carbide rod surface, and then pressed into a hard metal pipe sleeve compacts and then sintered together.

3. Squeeze method. The plastic compound mixture is extruded through a cut of the spout, the spout end of the installation of a large cylindrical hole formed spiral teeth containing these small teeth produce a rotating spiral during extrusion material through the formation of spiral groove slot.

Tungsten Carbide Double Helix Hole Rod Production Technology

Tungsten carbide double helix hole rod forming a double helix hole in the mold of its rough twisted to form a rotation, extrusion faster, shorter rough time in the mold mediator shape after extrusion die, the degree of elastic recovery, the greater the rough , while the longitudinal expansion is the result of the pitch increases. Therefore, the faster the extrusion speed, the greater the pitch of the blank.

Tungsten carbide double helix hole rod production technology, there are two that way and within the outer helix extrusion helix extruder way. The so-called outer helix extrusion way in the mold design and manufacture, the use of the female mold die with a ribbed tank, forcing the fluid out of the material change direction, rotating manner extruded billets, extrusion billet to rotate the entire process manner. So-called inner helix extrusion methods, the use of the special structure of a twin-helix extruder, and the core rod extends through the extrusion helix. Use a helix drive to reach the spiral mandrel rotation effect.

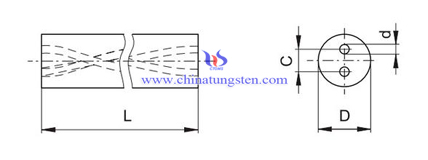

Tungsten Carbide Helix Rod with Cooling Holes

Tungsten carbide helix rod with internal cooling helix hole drill is mainly used in the production. Carbide drill with internal cooling helix holes, deep processing can improve the efficiency of drilling difficult materials to meet the needs of automatic processing lines and machining centers. In the cutting process, we can promptly get rid of metal debris in the working plane, extend the life of carbide tools, reducing replacement time, can greatly improve the processing speed. Internal cooling process is through an internal spiral tunnel, cutting edges will be transferred to high coolant under pressure. This can be either a spiral channel of the coolant due to the rapid and timely delivery, and rapid decrease in the process temperature; the same time as it directly to the internal processing of the front channels, which can be produced mechanically debris quickly and timely and clean out. Thus, it can achieve significant practical effect, its application both to extend the service life of their own, but also shorten the time the reorganization of machinery and equipment.

More Info>>

1.Tungsten Carbide

2.Tungsten carbide Bar

3.Tungsten carbide Rod

4.Tungsten Carbide Nozzle

5.Tungsten Carbide Button

6.Tungsten Carbide Inserts

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved