Tungsten Carbide Ball For Ballizing

What is Ballizing

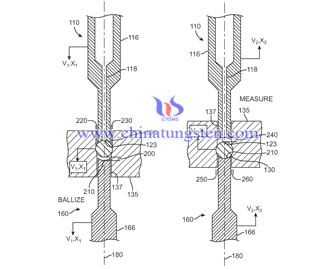

Ballizing is a method of finishing on internal diameter. It can give improvement in dimensional tolerance, roundness and surface finish.

Press a high precision tungsten carbide ball through an undersized hole in metal, to eliminate tool marks and to obtain dimensional accuracy. As the ball passes through the hole it does not remove material, but compresses it to form a much improved work hardened surface and a large improvement in hole tolerance.

Ballizing with Tungsten Carbide Balls

Ballizing is a fast low-cost process to sizing and finishing tubing and holes in metal. Pressing a slightly oversized tungsten carbide ball through the unfinished hole brings the hole up to desired size in seconds. The resulting surface finish is excellent and both size and finish results are very consistent. Industrial tectonics can provide application assistance.

Application

Tungsten carbide balls are used in applications requiring extreme hardness and resistance to wear and abrasion; and are able to withstand hard shocks and impacts. Our balls are made with 6% nickel binder or 9% nickel binder. Common applications for tungsten carbide balls include ball valves, flow meters, ball bearings, linear bearings, and ball screws. Tungsten carbide balls can also be used for coining and minting; as pivots, detents, and points or tips for gauges, tracers and comparators; and as metal balls for ballizing, hole sizing, gauging, and checking.

Characteristics

Tungsten carbide balls are ideal for applications where extreme hardness must be accompanied by high resistance to wear and impact. They are well-suited to elevated temperatures, corrosion, humidity, abrasion, and poor lubrication conditions.

Mechanical Properties

Ultimate tensile strength 220,000 psi

Ultimate compressive strength 643,000 psi

Transverse rupture strength 228,000 psi

Modulus of elasticity 98,000,000

Density (approx.) 0.54 lb./in.

Specific gravity 14.85-15.5

Electrically conductive slightly, magnetic

Low thermal expansion rate