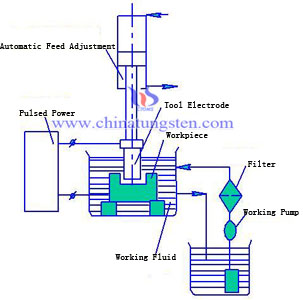

With the development of processing technology, tungsten carbide is widely used in mold manufacturing. But, as the material properties of tungsten carbide are different with hardened steel. It will Showing a certain processing characteristics, when it on the EDM processing, the hardened steel with more prominent problems in the processing efficiency, electrode wear and surface micro-cracks.

The main material for tungsten carbide EDM electrode is copper, iron and tungsten copper alloy, these electrode material with their own characteristics, can be used for different occasions. Copper is the most common for electrode material,which can be manufacture more complex electrode tool under cold extrusion processing. Tungsten copper with the best heat resistance, which is the best material for electrode tools, but it with high costs and highest unit price. In the early iron is widely used as tungsten carbide EDM electrode during the period of thyratron pulse power, and now is continue to use the EDM pulse power transistor for some mold makers. The three electrode materials used in tungsten carbide EDM electrode with the completely different wear characteristics. Find out the processing rules of tungsten carbide EDM electrode, which is able to provide some date under developing special carbide machining pulse power. Also with some practical significance on the development of EDM technology and improving the mold machining accuracy.

|

The main material for tungsten carbide EDM electrode is copper, iron and tungsten copper alloy, these electrode material with their own characteristics, can be used for different occasions. Copper is the most common for electrode material,which can be manufacture more complex electrode tool under cold extrusion processing. Tungsten copper with the best heat resistance, which is the best material for electrode tools, but it with high costs and highest unit price. In the early iron is widely used as tungsten carbide EDM electrode during the period of thyratron pulse power, and now is continue to use the EDM pulse power transistor for some mold makers. The three electrode materials used in tungsten carbide EDM electrode with the completely different wear characteristics. Find out the processing rules of tungsten carbide EDM electrode, which is able to provide some date under developing special carbide machining pulse power. Also with some practical significance on the development of EDM technology and improving the mold machining accuracy.

Through the experiment, the results showed as following:

1、Under the same conditions, the tungsten copper with the lowest weariness, the iron with highest weariness and copper in the middle of them.

2、When copper under electrode processing, a larger change in the pulse width and the machining current impact on its loss, the value increased, the electrode wear are also increased, but influence of electrode wear is not obvious for polarity selection.

3、When tungsten copper under electrode processing, the machining current and polarity selection will effect weariness, but with smaller affection by the pulse width. The processing current increased, the electrode wear is decreased. In the positive electrode, the loss is greater than the negative.

4、When iron under electrode processing, the pulse width and processing current will almost no affect the weariness. It will with lower wear under positive electrode, and will with higher wear under negative electrode.

These three electrode materials, the features of copper is with high thermal conductivity, tungsten copper is not only with high thermal conductivity, but also with high density, high refractory, and the iron is with lower thermal conductivity and lower density.So the tungsten copper with best corrosion resistance, iron with lowest corrosion resistance, copper is in the middle of them. So when they in tungsten carbide EDM electrode, the related weariness is different with each other.

From the thermal physical properties to distinguish, tungsten copper with hot cathode material characteristics, copper with cold cathode material characteristics, and iron in the middle of them. As the hot cathode material, if the temperature increased, tungsten copper’s hot electron is easier to release. When it as negative electrode for EDM machining, the current flows through the temperature rose, the heat emitted electrons increased. So the density of current will be higher than before, it will be better for workpiece.

Through the experimental study for copper, tungsten copper and iron in tungsten carbide EDM electrode, we could find the following results.

1、Polarity was be greater impact on the electrode wear, different material should choose different polarity, the tungsten copper is suitable as negative electrode.

2、Under the small pulse width, Since the protective film is not easy to promote, it is difficult to achieve low loss electrode.

3、Processing current will large affect electrode weariness, it will with different trends under the changed of processing current for different material. Electrode wear is falling for tungsten copper under the increased current, and copper will be increased.

More Info>>

1.Tungsten Carbide

2.Tungsten carbide Rod

3.Tungsten Carbide Nozzle

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved