The technologies of thermal spray coating are highly versatile devices that allow for the engineering of an almost a limitless number of coatings for an extremely wide range of industrial applications. A few examples of where thermal spray coatings can be found include: jet engines to protect components from high temperatures and oxidation, medical devices such as surgical instruments and orthopedic implants, agricultural components to enhance wear resistance, and electronic devices to provide electrical insulation or conductivity.

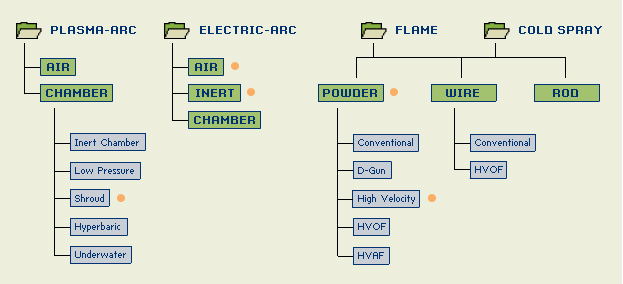

What is Thermal Spray?Thermal spray is a generic term for a group of processes that utilize a heat source to melt material in powder, wire or rod form. The molten or semi-molten material is propelled toward a prepared surface by expanding process gases. The particles quench rapidly, upon impact with the surface, and bond with the part. Subsequent impacting particles create a coating buildup, see figure 1. The thermal spray processes include the following:

Just like the diversity of the technologies of thermal spray coating, the types of materials that can be used to produce coatings, and the materials onto which coatings can be deposited, are very wide in variety. At Thermal Spray Technologies we like to use the philosophy that the imagination is the only limitation to what can be produced using thermal spray coating.

Coating Materials

Almost all metals can be thermal sprayed to produce coatings. Many plastics can also be thermal sprayed, especially plastics that have a good melting range. With some of the thermal spray processes capable of generating temperatures as high as 30,000 °F, (> 16,500 °C) very high melting point materials can be thermal sprayed such as oxide ceramics. In general, if a material melts there is a very good chance the material can be used to create a thermal spray coating. Even materials that sublime in many cases can be used in thermal spray coatings. One common method to produce a coating with a material that sublimes is to combine it with a material that does melt. The material that melts will act like a cement when the two materials deposit together to create a composite coating.

Even though thermal spray coating processes are capable of producing very high temperatures, the energy of the processes can have minimal effects on the materials being coated. The core of a process' energy is within or just outside of the thermal spray device. Since components being coated are typically a few to several inches from the thermal spray coating device the component absorbs little energy from the process. In some cases the source of the energy that the component has to adsorb is the energy in the individual droplets being deposited. These droplets may be at very high temperatures when they deposit but because they are very small, their overall thermal energy content is low. These characteristics make it possible to coat heat sensitive materials such as carbon fiber composites, plastics, thin metals, and even paper.

More Info>>

1.Tungsten Carbide

2.Tungsten carbide Balls

3.Tungsten carbide Burrs

4.Tungsten Carbide Inserts

5.Tungsten Carbide Plates

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved