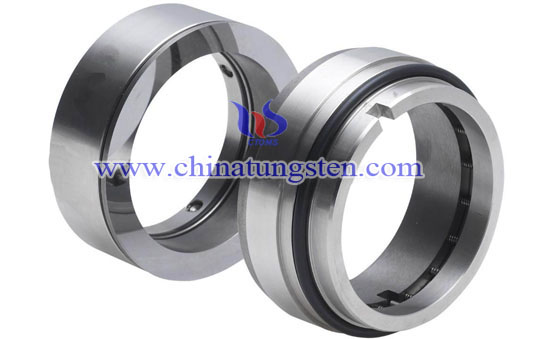

Tungsten Carbide Mechanical Seals

Definition

Tungsten carbide seal is made from the main component of high hardness refractory metal (WC, TiC) powder, add the related additives of Co, Ni or Mo. After pressing, and then sintering in vacuum furnace or hydrogen reduction furnace. Tungsten carbide mechanical seals consist of two parts, a part is hardening phase, and another part is Binder metal.

Properties

Tungsten carbide mechanical seals with excellent properties of high hardness, wear resistance, strength and toughness, high heat-resistant and corrosion-resistant. Even if in the temperature of 500℃, the products will also keep unchanged, and will have very high hardness in 1000℃.

Application

Tungsten carbide was widely used as cutting tools, such as turning, milling, planer, drill, boring and so on. Now the new tungsten carbide cutting tools are equal to several hundred times the carbon steel.

Features

1. Tungsten carbide seals is the most wear seals.

2. Tungsten is 10 times harder than gold, 5 times than steel tool, 4 times than titanium.

3. As the high hardness, tungsten carbide seals are able to keep their shape with the longest time.

4. Tungsten carbide seals are also called "Permanently polished ring".

5. Tungsten carbide seals will never bend.